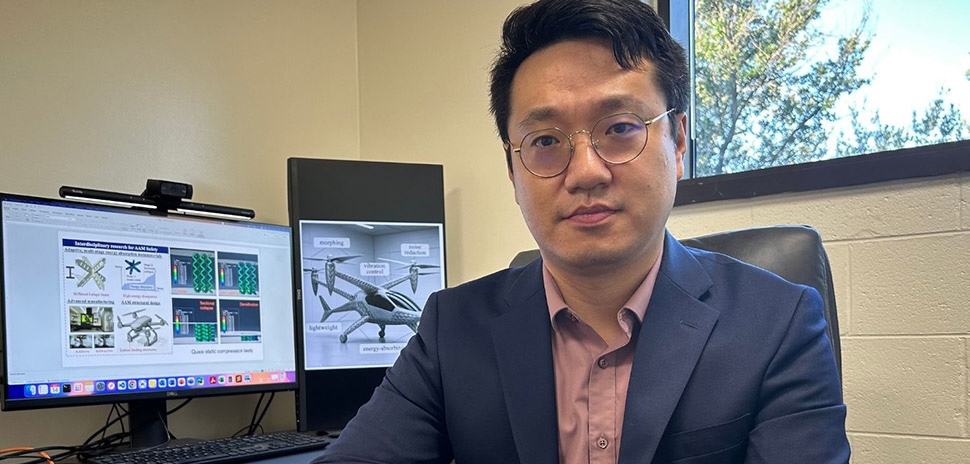

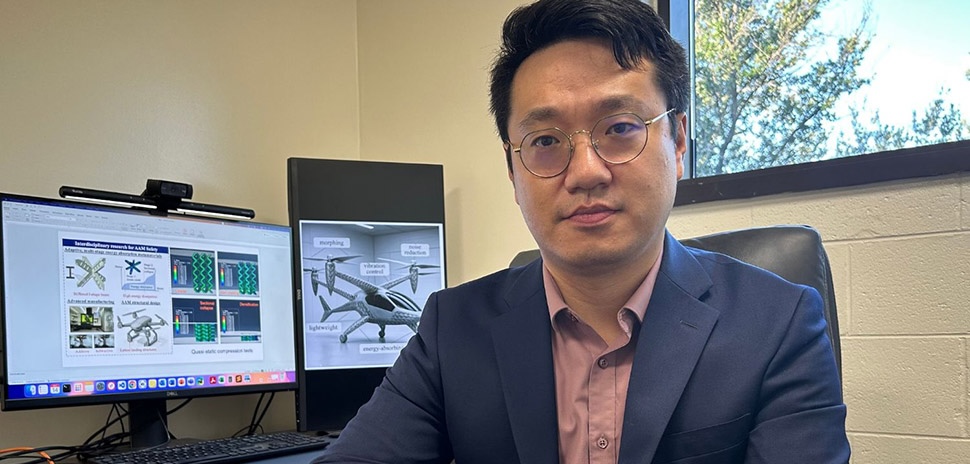

Dr. Xin (Jeffrey) Liu [Photo: UTA]

NASA is investing $750,000 in UT Arlington research aimed at one of the biggest hurdles facing advanced air mobility: making next-generation aircraft safer during frequent landings and unexpected impacts.

The three-year grant from NASA’s Minority University Research and Education Project program will support UTA researchers developing reusable, impact-resistant materials designed for emerging aircraft such as electric vertical takeoff and landing vehicles and urban air taxis. As NASA and industry explore more routine aerial transportation, the work targets safety challenges that traditional aircraft “were never designed to handle,” UTA said.

Taking off and landing constantly in city environments

Advanced air mobility, a priority research area for NASA, includes aircraft designed to operate more like automobiles than traditional airplanes. Unlike commercial jets that fly long distances with limited takeoffs and landings, these vehicles are expected to launch and land frequently, often in urban environments.

That shift introduces new structural demands, according to project lead Xin (Jeffrey) Liu, an assistant professor in UTA’s Department of Mechanical and Aerospace Engineering.

“Imagine every family having an aircraft,” Liu said in a statement. “You take off to work, land, then take off again to go home. That frequency of landing and takeoff creates very different safety challenges than traditional aircraft.”

Ensuring aircraft structures can absorb repeated impact forces without compromising passenger safety remains “a key barrier,” UTA said, as regulators and manufacturers evaluate how advanced air mobility vehicles would perform under real-world operating conditions.

Designing materials to absorb extreme impacts

Liu’s team is developing a new class of lattice metamaterials, engineered structures created through additive manufacturing that are designed to absorb impact energy in multiple stages. The goal: to protect aircraft during both routine landings and more severe impact events without permanently damaging the structure.

“The first step allows the material to recover its shape during soft landings,” Liu said. “If there’s a hard landing or collision, the second step dissipates a large amount of energy to reduce damage to the airframe and reduce impact loads on passengers and pilots.”

Unlike conventional impact-resistance systems that can deform or fail under repeated use, the material is designed to remain functional after multiple stress events. Reusability is a central focus of the research, particularly for aircraft expected to operate frequently.

“Current impact-resistance systems can break under repeated use or severe loading,” Liu said. “We want a new material that can be reused and still provide strong impact resistance under severe conditions.”

The material’s performance is driven by its internal geometry rather than its chemical composition, UTA said. By designing the structure at the microscale, the research team can control how it deforms under different load conditions.

“It’s not a natural material. It’s designed,” Liu said. “We design the structure, fabricate it using additive manufacturing, and test whether it performs well for specific impact-resistance purposes.”

From digital design to physical testing

The project combines computational modeling, additive manufacturing, and experimental testing to evaluate how the materials perform under different impact conditions. Once designed, the lattice structures are fabricated using high-precision additive manufacturing techniques and tested to assess their real-world performance.

While the primary focus is advanced air mobility aircraft, the research could also apply to space and satellite systems, where structures face similar risks from debris impacts.

A collaborative effort

Liu said the NASA-funded work brings together researchers across UTA, including colleagues in mechanical and aerospace engineering, as well as collaborators at the University of North Texas and industry partners.

“This is teamwork,” Liu said. “We have strong collaborations inside our department, across UTA, and with external partners. Everyone is contributing to this project.”

In addition to his faculty role, Liu holds a joint appointment with the Institute of Predictive Performance Methodologies at the UTA Research Institute in Fort Worth, connecting the research to applied engineering and defense-focused work in the region.

What comes next

Over the next three years, Liu and his collaborators will move the material from computational design to laboratory-scale testing, a step toward validating its performance under realistic impact conditions.

“When NASA announced calls for research to improve safety in advanced air mobility, I saw that this material had real potential to address that challenge,” Liu said. “We applied and, fortunately, received the funding.”

The work represents an incremental but critical step toward improving safety as advanced air mobility technologies continue to evolve, UTA said.

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.

R E A D N E X T

The investment strengthens UTA’s pipeline for high-demand engineering talent and supports research on AI-enabled safety systems for nuclear plants.

A new satellite campus is adding hands-on training, lab capacity and startup support to Dallas’ growing life sciences ecosystem.

Dallas Innovates, in partnership with the Dallas Regional Chamber, once again is recognizing the most innovative leaders in AI in Dallas-Fort Worth. From visionaries and mavericks to transformers and academics, AI 75’s class of 2025 are the AI pacesetters you need to know now.

A study found the air-powered wearable reduced muscle activity by as much as 22% during lifting tasks, pointing to a potential way to ease strain in industrial settings.

University of Texas at Arlington reported its projects contributed $59 million to the national economy last year, an increase of 39% from 2023, according to a new report from the Institute for Research on Innovation and Science (IRIS).